|

| ||||||||

In today’s competitive marketplace—with suppliers, trading partners, and logistics providers spanning the globe—it’s imperative for companies to have real-time end-to-end visibility and control of their supply networks, ensuring that fluctuating customer demands are met and revenues maximized.

Ariba’s new Forecast Collaboration plays an essential role in ensuring that suppliers have the right information beforehand to plan their inventory so they can meet customer demand. Buyers can now share forecasts and receive forecast commits for direct materials from their suppliers.

Forecast visibility

Manufacturing companies increasingly have moved away from the self-run process of building their final product in-house, stocking it, and then waiting to receive sales orders to trigger shipments.

Forecasting is typically generated as part of the Material Requirement Plan (MRP) from the buyer’s ERP system. Sharing this critical information with suppliers is of immense value because it is typically beyond the frozen horizon, which the period after which no planning can occur due to lack of information.

Forecasts offer the following benefits:

- They enable suppliers and buyers to manage demand and capacity.

- They allow suppliers to better plan to meet customer demand and improve service levels.

- Improved service levels can lead to increased sales and anticipated order-flow and fill-rate improvements.

- They can lead to a measurable reduction in Inventory to meet customer requests.

Forecast commit

Traditionally ERP systems were designed to plan and execute within a company’s four walls. However, most manufacturing today is outsourced in key industries, such as high tech and discrete manufacturing.

The outsourced operations are managed by another ERP system at a transaction partner. So, the supply chain is represented in multiple ERP systems with their own planning and execution requirements.

Contract manufacturers are an extension of the buyer’s manufacturing operations. To gain visibility and control over this extended supply chain and manage the demand/supply volatility, buyers must share their forecasts and receive commitments from contract manufacturers or component suppliers to be able to commit to the end customer’s demand.

The most robust supply chains use advance planning that leverages forecast collaboration and the extended process of having the supplier commit to the forecast.

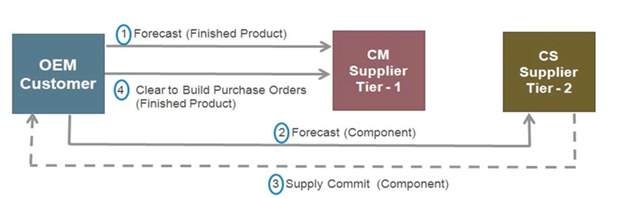

The following figure shows a simple example of collaboration flow in a multi-tier supply chain:

Forecast collaboration process

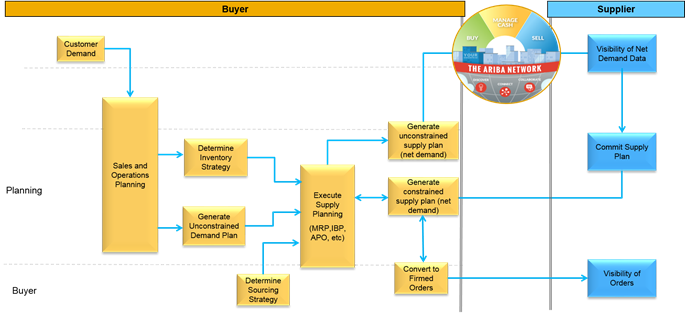

The forecast collaboration process is typically initiated by the buyer or the OEM from their MRP system, as the following figure shows.

The input for the MRP is actual demand from customers. Execution of the plan results in net demand data or what Ariba calls a forecast. The MRP-generated net demand is typically sourced, constrained by production lot sizes and lead time based on the supplier, and netted based on the current inventory levels.

Depending on the buyer’s ERP system, net demand is represented by the following types of documents:

- Purchase requisitions

- Planned orders

- Scheduling agreement releases with limited forecast zone

Forecast collaboration transactional flow

Ariba’s Forecast Collaboration makes planning for future demands much smoother.

Forecast Collaboration gives trading partners the following capabilities:

- Buyers send forecast data to suppliers.

- Buyers communicate demand lead time to suppliers.

- Suppliers view forecast changes for each time period.

- Suppliers view data in an aggregated format in days, weeks, months, or years. They can also download data in CSV format.

- Suppliers commit to the forecast data sent by buyers.

- Suppliers see deviations between forecast and commit data.

For more information on Ariba’s new Forecast Collaboration, see the SAP Business Network Collaborative Supply Chain Release Guide.

SAP Business Network for Procurement & Supply Chain